Precision-driven

Reliable and Efficient Packaging

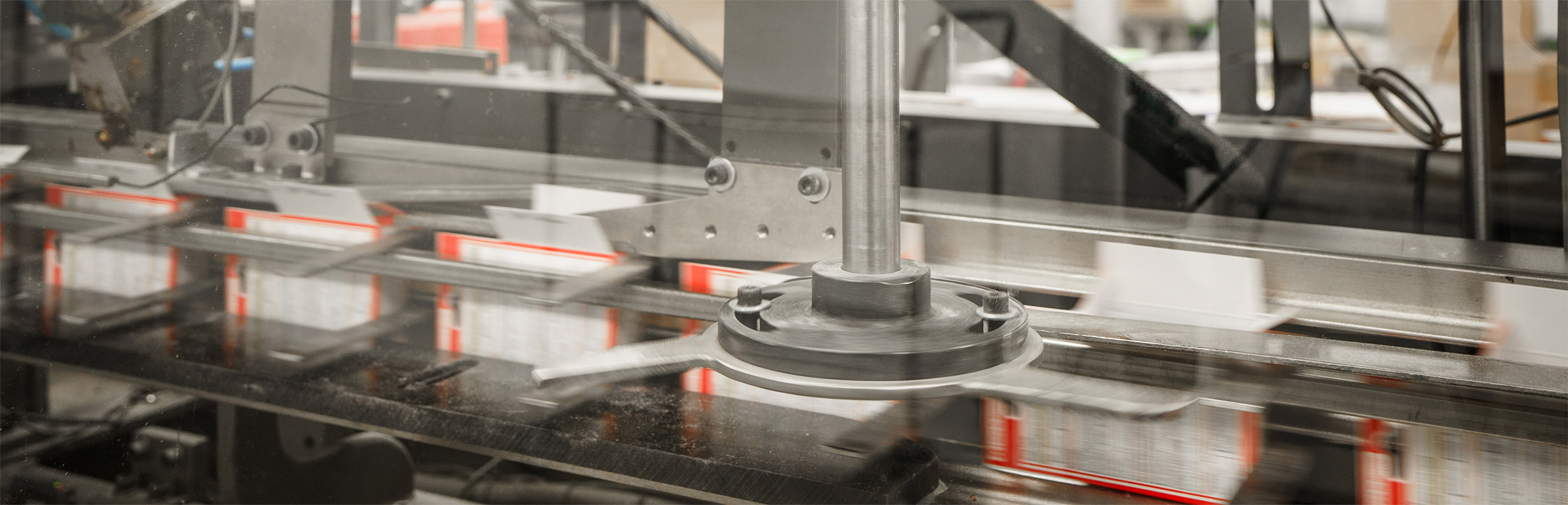

At Tenco Assemblies, Inc., our diverse packaging capabilities are tailored to meet your unique needs with precision and care. From cartoning , shrink wrapping, and labeling to blister carding, kit assembly and POP displays, we have the expertise and advanced equipment to handle it all. We also offer specialized rework and package salvage operations to ensure your products are always market-ready. With a focus on quality and efficiency, Tenco ensures your products are in capable hands at every stage.

Expertly-managed

Process Capabilities

Cartoning

Pouches, Bagged product,

Bottles, Multiple item kits

5 Cartoning Lines

Capacity (8) Hours: 150m/8 hour day

Capacity annually: 36,000,000

4 Jones Vertical

The Jones Vertical Cartoning Machine is a high-speed, versatile packaging solution that efficiently forms, fills, and seals cartons vertically. Its precision and reliability make it suitable for a wide range of product sizes and types, ideal for both small and large production volumes.

1 MGS Horizontal

The MGS Horizontal Cartoning Machine offers efficient and precise packaging solutions, excelling in horizontally packing and sealing cartons at high speeds. Its robust design and ease of use make it ideal for diverse production needs.

Shrink Wrapping

BOGO’s and Multiple Product

Marketing Projects

2 Shanklin F-5 Automatic Lines

Capacity (8) Hours: 50m / day total 8 hours

Ability to add equipment for auto labelling of special value and UPC labels

Description

The Shanklin F-5 Automatic L-Sealer is a high-performance shrink wrapping machine known for its efficiency and consistent output. It quickly seals products in film, offering fast operation and easy integration into existing production lines.

Labeling/ Overlabeling

Full panel, bonus labels, BOGO,

UPC labeling, etc

Automatic Labeling Lines

For cartons, blister cards, bottles, etc

4 Advanced automatic labeling lines

Our facility features four advanced automatic labeling lines, each capable of processing 30 to 40 million labels per line over an 8-hour shift. Designed for speed and precision, these lines efficiently handle large-scale labeling projects with minimal downtime, ensuring high-quality output and rapid turnaround to meet demanding production schedules.

1 Specialized bottle labeling line

Our facility features a specialized bottle labeling line capable of handling 20 to 30 million labels per 8-hour shift. Engineered for precision and efficiency, this line supports various bottle sizes and shapes, ensuring consistent label application. Ideal for high-volume operations, it enhances product appearance while meeting strict labeling standards, ensuring efficient production and high-quality outcomes.

Blister Carding

Alloyd Blister Sealers

Dimension related: typical 70m cards/ day total

2 Alloyd Blister Sealers, 6 station & 16 station

Our blister carding capabilities are supported by two Alloyd Blister Sealers, featuring a 6-station and a 16-station setup. These machines enable us to produce blister cards with exceptional efficiency and precision. With a combined output of typically 70 million cards per day, our facilities are well-equipped to handle substantial volumes, ensuring fast turnaround times for projects of any scale. This capability allows us to meet diverse client demands in packaging consumer products securely and attractively.

Form Fill & Seal

Form Fill & Seal Flow Wrapping

Dimension related, 10-50m / 8 hour shift

llapak Carrera 1000

Our form fill and seal flow wrapping capabilities are enhanced by the Ilapak Carrera 1000, a robust and versatile machine designed for high-efficiency packaging. Capable of handling 10 to 50 million units per 8-hour shift, this machine excels in precision and speed, making it ideal for a wide range of product sizes and types. The Carrera 1000’s advanced technology ensures seamless operation and consistent quality, supporting our commitment to meet diverse packaging needs with reliability and excellence.

Kits & Displays

Kit Assembly & Fulfillment

Typically 10-20m / day

Description

Our kit assembly and fulfillment services are designed to handle substantial volumes efficiently, with capabilities of assembling and fulfilling 10 to 20 million kits per day. This process is supported by both manual and cartoning line operations, allowing for flexible handling of various product types and packaging requirements. Our skilled workforce, combined with advanced line operations, ensures precise assembly and rapid fulfillment, making us a reliable partner for comprehensive kit packaging solutions.

Repackage

Rework/ Salvage Operations

200% Inspection projects

Description

Our rework and salvage operations feature comprehensive 200% inspection projects, ensuring utmost product quality and integrity. We also create tailored point-of-purchase (POP) displays for counters and club stores to maximize visibility and engagement. Additionally, our efficient sample mailing services support effective product promotion. These integrated services are designed to meet precise client needs for quality, display, and distribution.

Download our Comprehensive Capabilities Brochure

Contact Us

Request a Quote

Contact Form (Request a Quote)

"*" indicates required fields